Answer

- i) manual equipment ii) power assisted equipment iii)fully mechanized equipment

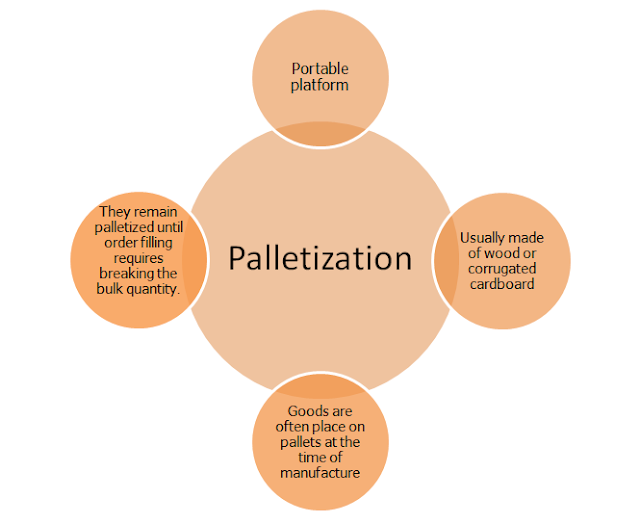

- Pallet is a portable platform, which goods are stacked for transportation and storage.

- i) To reduce handling cost ii) to increased space utilization.

- i) u-shaped ii) I-shaped

- i) promote the full space utilization ii) improve the materials handling efficiency.

Movement Equipment Choice

- Movement Equipment is differentiated by its degree of specialized use and the extent the manual power is required to operate it.

- There broad equipment categories : Manual Equipment, Power-Assisted Equipment, Fully Mechanized Equipment.

- Combination these 3 categories is generally found within a materials handling system rather than a single category used exclusively.

MANUAL EQUIPMENT

- Hand operated, material handling equipment such as 2-wheeled hand trucks and 4-wheeled platform trucks provides some mechanical advantages in movement of goods and requires only modest investment.

- Generally, manual equipment flexibility and low cost make good choice.

- Example of manual equipments are carpet handling, furniture handling, pipe handling.

carpet handling

POWER ASSISTED EQUIPMENT

- By using Power assisted equipment, materials handling can be speeded up and output per worker-hour increased.

- The example of power assisted equipment is forklift, crane, elevators and hoists.

FULLY MECHANIZED EQUIPMENT

- With computer-controlled handling equipment, bar coding and scanning technology, some materials handling system have been developed that come close to full automation.

Storage Equipment Choice

- Storage quipment can be defined as equipment used for holding or buffering materials over a period of time. Some storage equipment may include the transport of materials (e.g., the S/R machines of an AS/RS, or storage carousels). If materials are block stacked directly on the floor, then no storage equipment is required.

- In a way, storage is a temporary halt in materials flowing through a warehouse.

- Storage aids promote the full space utilization and improve the materials handling efficiency

- Rack also aids in rotating stock as in first-in-first-out inventory control system.

- Other available storage aids include shelf-boxes, horizontal and vertical dunnage, bins, U-frames.

As u can see below, there are example of available storage

Bins

Horizontal Dunnage

U-frames

Vertical Dunnage

Picture :D

WPC Pallet

stacker crane

Forklift

container flow rack

Quiz~

ii) Define the pallet

____________________________________________________________

iii) Give 2 (two) objective of Material Handling

iii) Give 2 (two) objective of Material Handling

iv) Give any 2 (two) operational design

v) Give any 2 (two) of storage aids

Section B

1.

With appropriate example, briefly

explain type(s) of space layout.

2.

Imagine you have just open new

factory plant production for car manufacture in Shah Alam, as manager define

and explain how you want to decide about how the movement of material into your

factory plant production?

3.

Explain the advantages and

disadvantages u-shape layout.

4.

Briefly explain any 4(four) the

basic requirement of warehouse.

5.

State and explain how to store

the product in the warehouse.

Load Unitization - Space Layout

Here we provide note about Material Handling Consideration. We hope that you guys can be enjoyed reading this note.

Material Handling Consideration

Objectives:-

- to reduce handling cost

- to increase space utilization

Material Handling efficiency can be improved along four(4) lines:

- loading unitization

- space layout

- storage equipment choice

- movement equipment choice

LOAD UNITIZATION

Principle in material handling is material handling economy is directly proportional to the size of load handled.

- As the load size increases, the fewer the number of required tips to store a given quantity of goods and the greater the economy.

- The number of trips is relates directly to the labor time necessary to move goods.

- Efficiency often can be improved through consolidating a number of small packages into a single.

- Referred to as load unitization and is most commonly accomplished through palletization and containerization

SPACE LAYOUT

Location of stock in the warehouse directly affects the total materials-handling expense of all goods moving through the warehouse.

Basic requirement for layout are :-

- Receiving

- Storage

- Order Processing (assemble,order picking,packaging)

- Office

- Miscellenous (toilet,mosque,pantry,washroom)

- Recouping Area

- Shipping

Type of Warehouse can be divided into two(2):-

example of u-shape layout

Material handling's video

Today is Sunday. Sunday sinonym with holiday. But for us, there is no holiday until this assignment finished. Hahaha :D

Alright, we straight to the point and do not turn away.

Here we provided you some video that related to the 'Material Handling'..

We hope that with this video can improved your understanding about this topic, Material Handling :)

Thank You for reading :)

We will back with example of material handling equipment, stay tuned ;D

Subscribe to:

Comments (Atom)

.jpg)