Here we provide note about Material Handling Consideration. We hope that you guys can be enjoyed reading this note.

Material Handling Consideration

Objectives:-

- to reduce handling cost

- to increase space utilization

Material Handling efficiency can be improved along four(4) lines:

- loading unitization

- space layout

- storage equipment choice

- movement equipment choice

LOAD UNITIZATION

Principle in material handling is material handling economy is directly proportional to the size of load handled.

- As the load size increases, the fewer the number of required tips to store a given quantity of goods and the greater the economy.

- The number of trips is relates directly to the labor time necessary to move goods.

- Efficiency often can be improved through consolidating a number of small packages into a single.

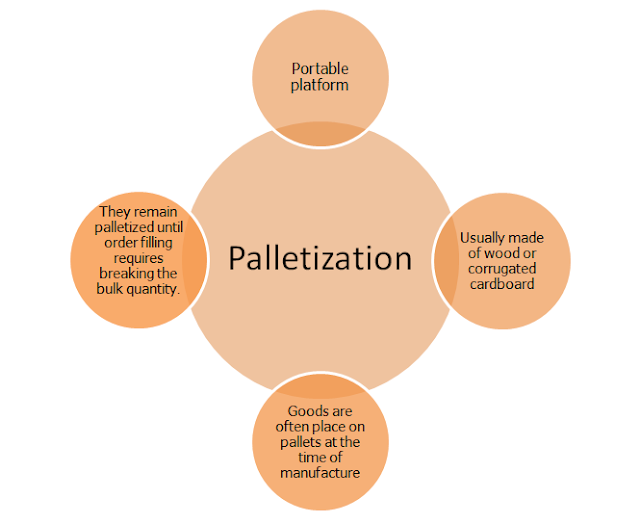

- Referred to as load unitization and is most commonly accomplished through palletization and containerization

SPACE LAYOUT

Location of stock in the warehouse directly affects the total materials-handling expense of all goods moving through the warehouse.

Basic requirement for layout are :-

- Receiving

- Storage

- Order Processing (assemble,order picking,packaging)

- Office

- Miscellenous (toilet,mosque,pantry,washroom)

- Recouping Area

- Shipping

Type of Warehouse can be divided into two(2):-

example of u-shape layout

No comments:

Post a Comment